STIRRED not SHAKEN – TURNED not FOLDED – BLENDED not BLOWN

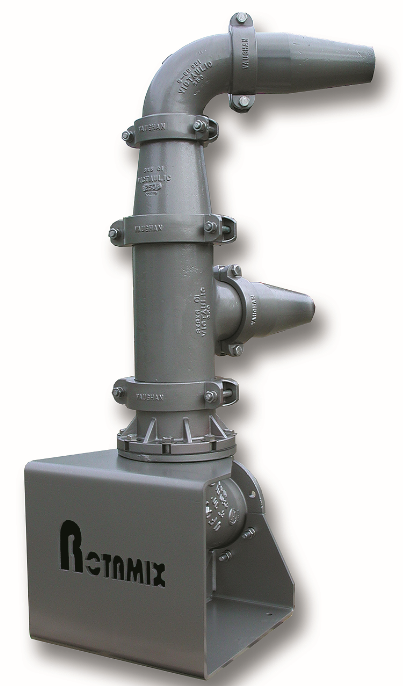

Tank mixing is an important requirement in many waste water and process applications and the Vaughan ROTAMIX

system is widely acknowledged as the most cost-effective methods of pumped mixing available today.

Take a look at these key benefits

- Relatively simple to install

- Easily maintained with no internal mechanical components

- VAUGHAN CHOPPER PUMP reliability at the heart of the system

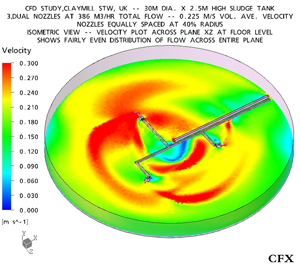

- Bespoke design to suit any tank size, shape or geometry

- Guaranteed and Effective mixing with reduced cleanout costs

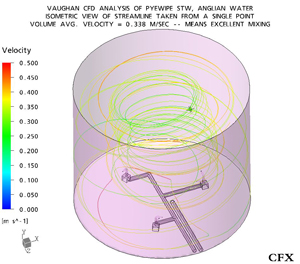

- CFD Computerized Fluid Dynamic models for proven capability

RECENTLY COMPLETED TANK MIXING INSTALLATIONS

The Vaughan ‘Chopper’ pump at the heart of every mixing system.

A LIQUOR BUFFER TANKA completed tank and mixing system.

The 20m diameter liquor tank is roofed as they are able to harvest/recover gas from each covered tank due to our mixing systems.

The Concept

Rotamix system incorporates several basic principles of physics and hydraulics, including uniform field of flow, vortical field of flow and surface contact. This combination of this unique mixing system optimises solids contact due to the homogeneous state.

Dual-Zone Mixing

The dual-zone mixing pattern is a combination of both uniform and vortical fields of flow. In a uniform field of flow, the entire contents rotates as a solid unit with the highest velocity at the outside. In a vortical field of flow, fluid velocities are the greatest at the centre, which creates a vertical-axis vortex. The Rotamix system combines both uniform rotation and a vertical vortex, creating unique dual-rotational zones. With dual-zone mixing, average velocities are higher and more steady, so solids are prevented from settling in the centre.

‘The ROTAMIX systems give us confidence that the sludge within our digesters is fully mixed ensuring consistent biological treatment can occur, minimising blockages throughout the sludge system and being part of why our sites continue to provide good gas flows. We have not found a different system which provides the same performance’ Southern Water 2022

Induced Flow

velocity nozzles also increase the effective mixing volume by inducing entrained fluid, significantly increasing the overall mixing effect. These high velocity nozzles induce flow over a longer distance, thus generating an overall effect over a larger volume.

Surface Contact

Finally, the Vaughan Chopper Pump not only eliminates nozzle clogging, but also optimises surface contact by constantly reducing solids size and so increases total surface area.